Tel: +86-379-60866465

Rebar bending machine

GL-L32T5 CNC Steel bar bending center GW40 Rebar bending machine GW50 Rebar bending machineRebar cutting machine

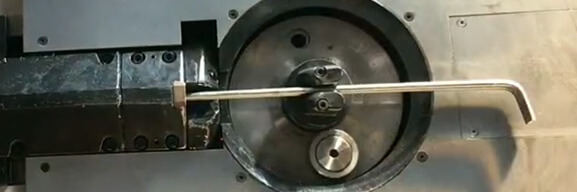

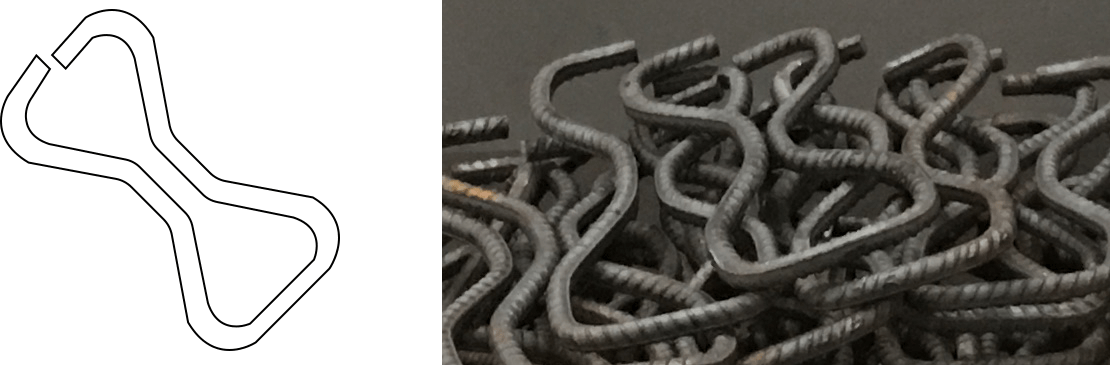

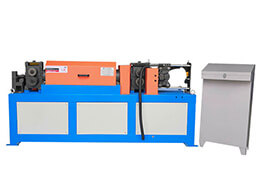

GT6-14 CNC Hydraulic Bar Straightening and Cutting Machine GL4-16A CNC Hydraulic Bar Straightening and Cutting Machine GL-120KN CNC rebar shearing lineRebar stirrup and spiral bending machine

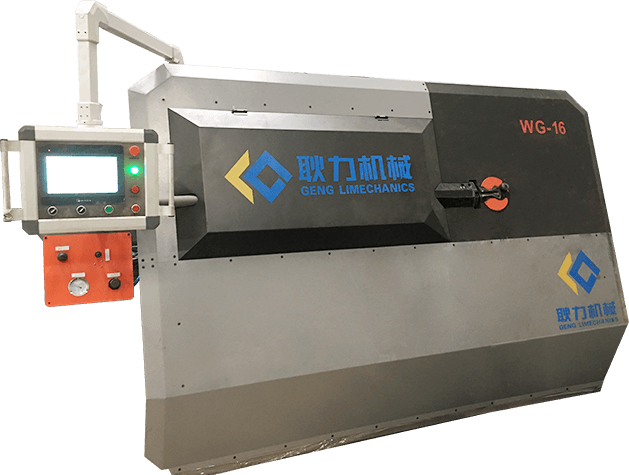

GL-L32T5 CNC Steel bar bending center WG16 CNC Stirrup bending machine SWG12 CNC Stirrup bending machine